Knowing and controlling the moisture content of materials from the introduction of the raw materials to the packaging of the final product, is key to maximising efficiency, optimising yield and producing a high-quality, consistent product

Variation in the moisture content of the raw materials has historically presented a challenge to feed processors. The raw ingredients' moisture content varies depending on the prevailing environmental conditions during harvest, transportation, and storage.

The perfect solution is to constantly measure the flowing materials' moisture content and correct moisture variations in real-time. Sophisticated, reliable, and affordable moisture sensors can simply control the moisture content throughout the entire process.

Why should you measure moisture?

1. Raw materials vary in moisture content, and this variation leads to weighing discrepancies. This affects both the final yield and causes variation in the nutritional value.

2. Accurate control of the moisture during the drying process prevents under-drying and over-drying. Over-drying material uses excessive energy, reduces the yield, and can damage the material being dried. Under-drying leads to potential mycotoxin growth and reduces the storage life of the material.

Choosing to rely on a moisture sensor that can measure to a precision of +/-0.5% instead of 1.0% only seems to be a slight improvement but it is possible to offer an alternative view. If you can consider that the process is drying material from 20.0% to target a maximum moisture of 14.0% then, as can be seen in Figure 2, the 0.5% improvement in the sensor precision yields a much more considerable 7.14% energy saving as the energy input is proportional to the moisture loss.

Below is a table showing energy savings from 0.5% improvement in target precision

|

Starting Moisture |

Target |

Tolerance of Control |

Required Moisture Control Set Point |

Amount Dried |

Energy Required |

|

20.0% |

14.0% |

+/- 1.0% |

13.0 % |

7.0 % |

733.91 kWh |

|

20.0% |

14.0% |

+/- 0.5% |

13.5% |

6.5 % |

681.49 kWh |

|

Energy required is calculated using the Hydronix Dryer Savings Spreadsheet |

7.14% energy saving |

||||

Characteristics of a good moisture sensor

When selecting a sensor, it is essential to ensure that it is fully temperature stable and completely linear over the working range at which you wish to operate.

Moisture sensors need to be installed in contact with a stable and consistent material flow. Different sensor models are available, which ease different mechanical installations, allowing straightforward installation into mixers and screw or belt conveyors on an existing plant to improve every part of the process, reducing waste, improving quality, saving time and effort.

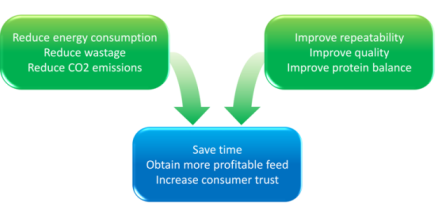

Benefits

By controlling the moisture during the weighing up of the raw materials, it is possible to:

• Correctly control the protein content of the final pellet

• Guarantee superior product quality

• Increase in the yield from a raw material

• Reduce spoiled material

• Optimise of the energy input into the processes

• Produce a consistent feed with a repeatable and homogenous nutritional value

• Obtain a reliable shelf life.

Using a consistent blend of usable materials and maintaining a constant final moisture target saves energy and extends the time between dryer maintenance.

The Hydronix XT range of sensors use an industry-leading Digital Microwave Measurement Technique and have a proven track record in these types of applications throughout the world.

Visit www.hydronix.com for more information.