When processing corn (or maize), from farms for animal feed production, the water content of the raw material constantly varies, and must be optimised, to prevent having spoiled material in the storage silos, or wasting energy by over-drying

Many dryers are controlled by testing a sample of material which has been processed in the laboratory, and then setting the appropriate drying rate, and temperature settings.

The best laboratory test is only valid for the material collected; so to control a continuous process, it is necessary to take more frequent samples. While 10 to 20 samples per day is competitive enough, the possibility of testing 25 samples every second is unbeatable.

Modern digital in-line moisture sensors have a proven track record in achieving high speed measurement of process flows, with more repeatable accuracy than periodic testing.

A Hydronix Hydro-Mix XT Digital Microwave moisture sensor was installed in the outlet of a corn dryer, to achieve online control of the moisture for the most profitable results.

Performance before sensor installation

Corn received from farms continuously varies, so the moisture of material coming from storage silos can change 2% in as little as five minutes. To create an initial point of reference on the installation site, two samples were taken of the dryer output, 40 minutes apart and, when tested in the laboratory, gave moisture content of 11.2% and 13.6% respectively.

As the age-old dryer is controlled manually, it is not able to respond to changes in moisture rapidly.

The dryer would be running with a target of ensuring only 12.6% moisture; to ensure that the variation of +/-1.4% in the processed material, did not exceed the maximum moisture target of 14%.

Sensor Installation

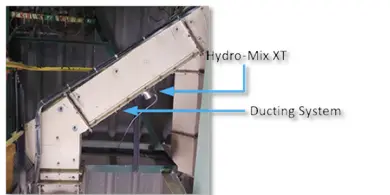

Photograph 1 shows the moisture sensor installed in the outlet of the dryer.

The sensor installation uses the Hydronix Ducting System, to ensure that a smooth and repeatable flow of material passes over the sensor, allowing a precise measurement of the moisture content of the corn.

The sensor measures the material moisture 25 times every second, and is connected directly to the PLC, to enable the control system to react to the change of moisture.

Result after installing the sensors

During trials, a continuous measurement of the moisture level of the grains, with accuracy better than +/- 0.5% was achieved, enabling the process target to be set higher, while still guaranteeing that the maximum moisture was not exceeded.

As shown in the table in Figure 1, the processing of the material started at the same moisture level. It and was dried to ensure it was below 14%, the improvement in the accuracy resulted in as much as 12.2% of energy saving.

| Starting Moisture | Target | Tolerance of Control | Required Moisture Control Set Point | Amount Dried | Energy Required |

| 20.0% | 14.0% | +/- 1.4% | 12.6 % | 7.4 % | 776 kWh |

| 20.0% | 14.0% | +/- 0.5% | 13.5% | 6.5 % | 681 kWh |

| Energy saving from installing Hydronix moisture sensors | 12.2% | ||||

Figure 1: Energy Savings from the improvement in target precision

Hydronix sensors

The Hydro-Mix XT is part of the Hydronix range of Digital Moisture Measurement sensors, which are constructed of stainless steel, and have abrasion-proof ceramic measuring faceplates. The sensors are designed to be installed flush-mounted, with the sidewall or floor of a processor, or it can easily be integrated into existing ducts, using the Ducting Systems, allowing the material to flow freely over the faceplate, without causing any build-up.

Sensors can be installed at several stages during the processing of corn, including

-Raw material delivery to site

-Before and after storage

-Before and after drying

-Processed material shipping from site

The unique Hydronix digital measurement technology has a direct, linear relationship with the moisture, and is superior to older non-linear techniques such as resistive, capacitive, and analogue microwave sensors. As many as 25 readings per second, allow for real-time control of the silo storage moisture levels, ensuring there is a rapid reaction to the material changes.

When drying corn, there is a large reduction in the amount of energy wasted caused by the time delay between periodic sampling and subsequent dryer adjustment.