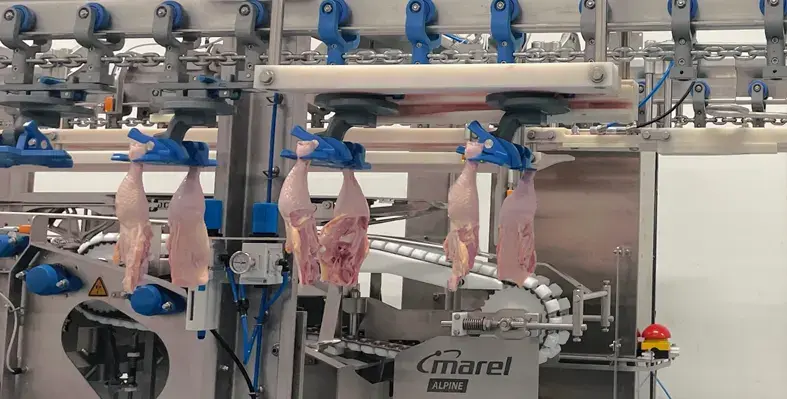

Given the high demand for deboned leg meat, the Anatomic Leg Processor Innovative New Evolution (ALPINE) represents a significant leap forward in anatomic leg processing

By maintaining top-level performance while handling a wide range of weights and reducing labor dependency, ALPINE addresses processors' needs for increased production volumes while also maximising yield and quality. A number of advanced technologies such as the Hip Dislocation Wheel have been used to realise ALPINE's high performance. This unique feature allows for precise control of the hip tilting movement─needed to achieve an anatomical cut─without exerting excessive force or removing the leg from the shackle. It results in improved performance and virtually inexistent leg loss.

In an attempt to further enhance accuracy and minimise errors, ALPINE incorporates advanced back piece separation and detection technology which prevents incorrectly cut legs. Optionally, processors can integrate a special module to remove groin skin automatically, meeting specific market demands while saving considerable manual trimming labour.

Easy operation

ALPINE is equipped with a user-friendly HMI touchscreen, making it easy to enter a recipe that matches the specific characteristics of the incoming flock. This automatically engages the proper machine settings to provide the highest possible leg yield.

The screen also shows performance data, enabling processors to monitor key metrics such as backpiece detection, leg loss, and unprocessed legs. Built-in machine software provides this real-time and historical performance data. Such proactive insights minimise the need for manual intervention and prevent downtime. ALPINE’s data-driven approach enables processors to maintain peak performance with minimal need for maintenance.

Wide weight range with consistent results

Designed to process high-yield anatomic legs across an unprecedented range of bird weights without requiring major adjustments, ALPINE's versatility is valuable for processors handling diverse flock weights. This enables them to optimise operations even in big bird processing markets.

Regardless of weight fluctuations, the result will always be consistent: a high-yield leg. Compatible with both water-chilled and air-chilled lines, ALPINE easily integrates into existing setups and pairs excellently with Marel's Thigh Fillet System, at a capacity of up to 7,200 products per hour.

Saving labour

Keeping legs within the shackles at all times enables ALPINE to practically eliminate product drops and minimise rework, downtime and labour. Digital operation, automated settings, reduced need for adjustments and precise performance monitoring further highlight its labor-saving advantages. Touchscreen control and the broad weight range further contribute to ALPINE’s efficiency, ease of use and consistently high yield.