Diesel generator sets have been a feature of many farms and food processing facilities for a long time and it’s not difficult to see why they are still probably the most flexible and cost-effective way to insure against interruptions in the mains electricity supply

One generator set brand, FG Wilson, has just marked 50 years in business, and this month, we talked with Managing Director, Ann Brown.

FG Wilson hails from Northern Ireland, a part of the world where farming and agriculture are built into the core fabric of the community, a place where it’s almost impossible to travel for 20 minutes without passing green fields and farming.

Ann says that this farming backdrop has often played a big part in the development of FG Wilson products. “There’s a long engineering tradition in Northern Ireland. Many of our engineers grew up around machinery and it’s been a big part of their lives. It’s always been quite common for many of our people to work with us and at the same time own and operate farms. That life experience has played a big part in the way a lot of our people look at product design. The weather environment here can be really harsh and when we’re designing products, that’s always in the back of our minds.”

In its simplest form, a diesel generator set has a diesel engine driving an AC generator / alternator which produces an AC electrical output. The engine and alternator are fixed to a rigid steel chassis which usually contains an 8 – 10 hour fuel tank.

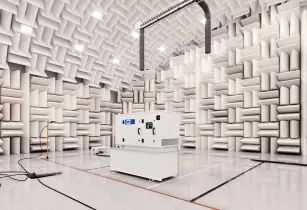

That’s been the basic principle for a long time and for several decades FG Wilson have been at the forefront in driving that concept to new levels. Designers of generator sets face a constant battle to control noise and heat. For FG Wilson, that means generator sets are designed to operate effectively in up to 50°C temperatures. That kind of sweeping statement is much easier said than done. Ann says, “This needs a really detailed understanding of airflow through enclosures, and it’s expertise which we’ve grown over decades to the point where we can count on a vast library of documented test data to support all of our design work. This is really important in high ambient temperature environments. It’s not difficult to put an enclosure around a generator set. It is much more challenging to make it work in a high ambient temperature.”

A range of enclosures protect generator sets from weather and also reduce noise to comfortable working levels. Enclosures are made of high grade or galvanised steel protected by powder coat paint which gives them automotive industry levels of finish. Their design is based on modular principles which means they have interchangeable components for easy on-site repair. Lift-off doors and access panels mean they also have good access for service and maintenance.

Control panels are where most interaction with generator sets occurs and these are designed to be compact and intuitive. Panels include traditional key-start analogue control panels for straightforward functionality and reliability; digital control panels suitable for use in mains failure applications, providing advanced metering, protection and diagnostics; and the next generation of advanced synchronising panels with integrated load management capability, able to synchronise up to 32 generator sets.

“What really marks out FG Wilson,” says Ann, “is the way products are validated and tested. Since 1990 we've installed over 600,000 generator sets with a total capacity of almost 90GW - more than the total installed mains electricity capacity of a country like the UK. In Africa, we’ve installed over 130,000 units with a total capacity of over 12GW, double the total installed mains electricity capacity of Nigeria. With that number of machines operating across the world, we take no risks with quality or performance. We don't accept engine performance data without validating it ourselves in the environmental conditions which our products will see. When someone buys one of our products, we can safely say that wherever it will be operating, it will have been tested for that environment.”

Also important to Ann is the way a generator set is sold. She says, “We've worked tirelessly to grow and develop a global network of distributors who offer automotive industry levels of service starting with product selection through to installation and a lifetime of support. They're trained by us and supported by our parts system which stocks over 11,500 parts and delivers three million parts a year, not only for our current products but also for legacy products.”

For Ann, product quality, design and customer support are the three guiding principles for FG Wilson: “The generator set industry isn't living on an island all on its own. More and more we’re feeling influence and behaviours from other industries. We all expect more from what we buy. And that means constantly challenging ourselves to improve.”

To find out more about FG Wilson, visit www.fgwilson.com