As we look to feed a growing world population, it is critical for the feed industry to find ways to increase the efficiency by which animals convert feed into protein while shortening the cycle time of production

New generations of healthy nutrition solutions, including combinations of feed technologies, will need to deliver sustained or increased levels of profitability through enhanced animal performance and livability to ensure a consistent supply of protein at an affordable cost.

Reducing the impact of variance in feeding value

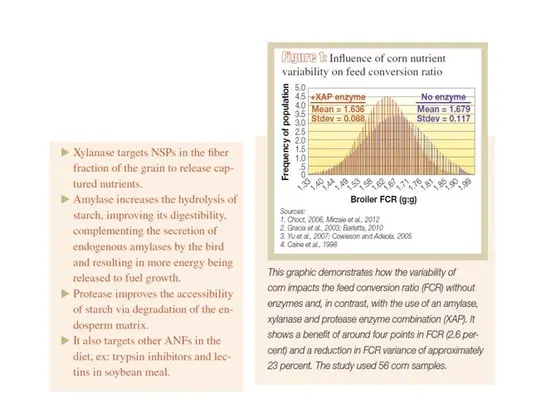

Dealing with variability in feed digestibility and feed cost are two of the main challenges facing animal producers. It is generally acknowledged that the lower and more variable the feeding value of individual raw materials, the greater the potential for feed enzyme response. Appropriate combinations of feed enzymes are therefore particularly valuable in diets containing cheaper, high-fibre ingredients, which contain higher levels of anti-nutritional factors (ANFs), such as non-starch polysaccharides (NSPs) and phytate. Corn is the most common feed grain used globally. However, its feeding value can also be very variable due to growing and harvest conditions, which can be improved with the addition of appropriate enzyme combinations.

Broiler trials have shown that variability in feed conversion ratio, caused by variability in corn and its digestibility, can be improved by a combination of xylanase, amylase and protease enzymes (Figure 1).

Achieving optimum feed efficiency

Enzymes can positively affect the gut microbiota through improved digestibility, for example, xylanases showed benefits in wheat-based diets for poultry in a Campylobacter jejuni challenge model (Fernandez et al., 2000). It was also noted that indigestible NSPs and trypsin inhibitors (TIs) both appeared to induce necrotic enteritis (NE) linked to Clostridium perfringens proliferation in chickens (Shojadoost et al., 2012). Both NSPs and TIs are well-known substrates for xylanase/betaglucanase and protease enzymes, respectively.

Maintaining gut microbiota balance

Probiotics have been defined as combinations of beneficial bacteria that maintain the gut microflora and assist with natural defences against pathogens (Patterson and Burkholder, 2009).

Bacillus probiotics are favoured for inclusion in animal feed due to their stability during steam conditioning and pelleting; their resistance to enzymatic digestion; and stomach acidity, which ensures delivery to the lower intestinal tract, as well as their effective colonization of the gut wall.

Benefits claimed for Bacillus include supporting optimum gut microbiota in young animals, counteracting stress, transportation, climatic change, mixing animals of different origin and overuse of therapeutics. In addition, they have been shown to help protect growing animals from colonization by coliforms and promote villi development in the gut lining, enhancing the animal’s ability to absorb nutrients (Lee et al, 2010). This is important, as gut metabolism in chickens accounts for 20 to 36% of daily energy expenditure (Cant et al., 1996).

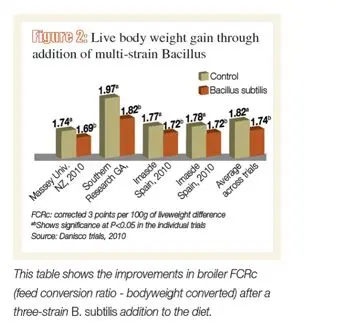

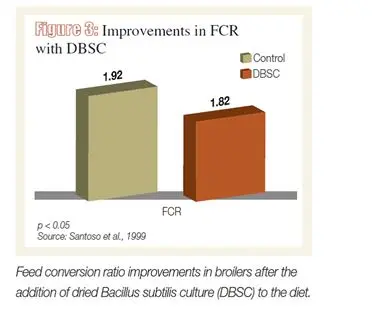

Trials with combined strains of B. subtilis have shown 4-5% improvements in FCR (Figures 2 and 3) and in an NE challenge model (Santosa et al. 1999) broilers maintained good performance during the period of challenge when probiotics were added to their feed.

The demand for more protein doesn’t only equate to meat, as eggs are a major protein source in many countries. After adding dried B. subtilis culture to layer diets, layer trials exhibited the following performance improvements: 2.8% in number of eggs/hen/day; 1.2% in egg weight; and 2.4% in egg mass/hen/day (Xu et al., 2006).

The same studies showed that egg shell strength was improved by 10.6%, protein levels in eggs by 3.1%, while yolk cholesterol was decreased by 12.2%. Also, 5.9% less feed was required to produce 1 kg of egg.

Achieving the optimum healthy nutrition solution

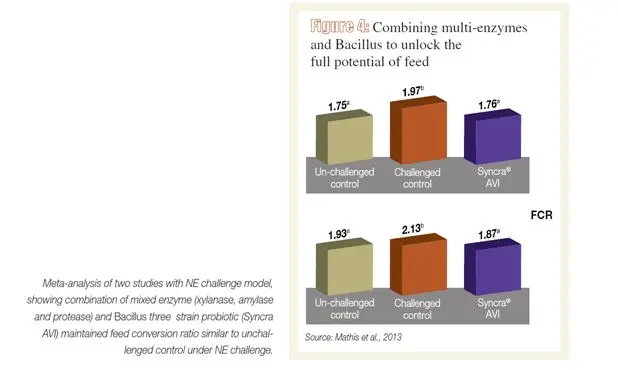

Multi-enzyme combinations of xylanase, amylase and protease can help producers improve performance while also supporting gut health. Bacillus DFMs have also been shown to provide healthy performance benefits. The logical conclusion would be that combining Bacillus probiotics and selected enzymes should unlock even more value by combining these benefits and helping producers supply high-quality protein more quickly and profitably.

In a meta-analysis of six broiler trials run under “low challenge” conditions, average improvements in body weight corrected FCR of 2.4% were seen, bringing a net benefit of around three-to-one in terms of return on investment.

In two studies using an NE challenge model with Clostridium perfringens, the same combination of Bacillus three-strain probiotic and xylanase, amylase and protease enzymes showed equivalent FCR to the unchallenged control (Figure 4).

As the pressure grows on poultry producers to reduce production costs without compromising bird performance or gut health, this combination appears to offer good opportunities to fully unlock the potential of feed.

-By Ajay Awati, senior scientist and development team lead at Danisco Animal Nutrition.