Marel’s ACM-NT system saves labor and adds intelligence

Wings, legs and breast are incredibly popular chicken pieces and a highly wanted sight on the world’s dinner tables. Cut-up chicken parts are often found in QSR restaurants too, such as the famous buckets. To keep up with the high demand, high-speed cut-up lines are needed to produce the required amounts of all kinds of chicken parts. At the same time, facing the labor shortage, processors need an automated process that requires the least human intervention.

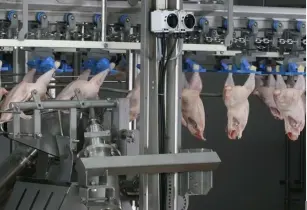

Marel’s ACM-NT stands for automatic modular in-line cut-up, capable of handling up to 7,200 broilers per hour. The system will handle both air and water-chilled products. It is a solidly proven solution, as it is in successful everyday operation with processors around the world, from USA to China and from Australia to Poland.

Labour issues

Cut-up and deboning departments need a large amount of skilled staff if they are not automated. Marel offers plenty of options for turning these processes into in-line automatic operations without losing yield or compromising product quality or presentation. Marel’s ACM-NT cut-up system is an excellent solution for cutting all required products. Thanks to its modular configuration using wing, leg and breast cutting modules, the system performs skilled cuts, which could earlier only be done manually.

Automating the cut-up department doesn’t mean that labour will disappear from the processing plant altogether. Job functions are, however, shifting away from real physical contact with meat and from heavy labour towards supervising and checking. Furthermore, equipment will always need proper maintenance and service. Manpower will be needed on a daily basis to keep all machines running at optimum efficiency.

Typical cuts

Marel’s ACM-NT is fully modular. If and when processing requirements change, modules can be moved or added. The system will cut carcasses into wing, front half and whole anatomic leg portions. If required, wings can be cut into separate inner and middle joint portions. In some markets, wings are cut with back meat, breast meat or both attached. ACM-NT’s wing cutter can be set to give these options too.

Depending on the filleting method afterwards, processors can choose to integrate a Breast Cap Cutter or a Front Half Cutter in the system. Cut breast caps are filleted in Marel’s AMF-i intelligent breast filleting system. Front halves can supply an FHF-XB system filleting system.

ACM-NT can automatically do virtually every wing, front half and leg cut required by processors worldwide.

Butcher quality

Users are particularly impressed by the high quality of the legs cut by the system; yield and presentation are as good as when legs are butchered manually. The secret of the ACM-NT’s JL-R anatomic leg module is that it 'pulls' rather than cuts legs from the back half. Legs retain their natural shape and there is no damage to the hip bone.

Virtually every wing, front half and leg cut required by processors worldwide can be done. Each part of the world has its own specialties, for which specific automated solutions have been developed. An example is the Second Joint Wing Cutter HPP, which cuts the centrepiece of the wing with as much first-joint skin attached to it as possible, following an Asian tradition.

Intelligence in cut-up

Cut-up lines make increasing use of intelligence to remove human bias from decision-making and ensure consistent top quality and consistent top yields. Super-accurate, up-to-the-minute, in-line weighing and vision systems provide the necessary input data, which is then processed by Marel Innova PDS software. Innova PDS can determine exactly how each carcass is to be cut, also which products to release for sale whole. Quite simply, Innova PDS enables processors to match incoming carcasses in the most profitable way possible to incoming orders for whole and cut product.