Marel’s automated ACM-NT cut-up solution offers almost limitless production flexibility, regardless of processing capacity

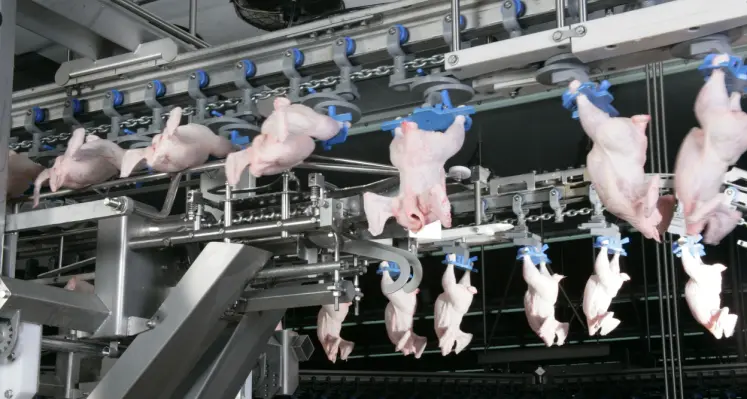

A good cut-up system is consistent, accurate, flexible if needed and gives high yields. Marel offers solutions for semi-automated, easy-entry, fast food and fully automated, order-controlled cut-up processes. Cone lines are suited to ease a mainly manual cutting process, while the ACM-NT Compact system can be a first step to further automation.

With its numerous module options, Marel’s high-performance and versatile automated ACM-NT cut-up solution has all the abilities to create the desired end-products. While producing for a QSR chain, the whole product may need to be cut up in a specific way and into a specific number of pieces. Using the appropriate modules in the ACM-NT line, these cuts can be made according to specification. Products are positioned perfectly, even at the highest line speeds. This results in producing the highest yields and percentage of A-grade cuts in the entire industry.

Combining the cut-up system with Innova production control software enables the user to make the very best use of an incoming product based on weight and quality and provides fully comprehensive reports on what has been produced.

For more information, visit: https://marel.com/en/products/acm-nt/