Sugar factory workers across Kenya have suspended a planned nationwide strike following breakthrough talks between the Government and the Kenya Union of Sugar Plantation and Allied Workers KUSPAW.

The decision came after high level crisis discussions held at Kilimo House, offering fresh hope for stability in the struggling sugar sector.

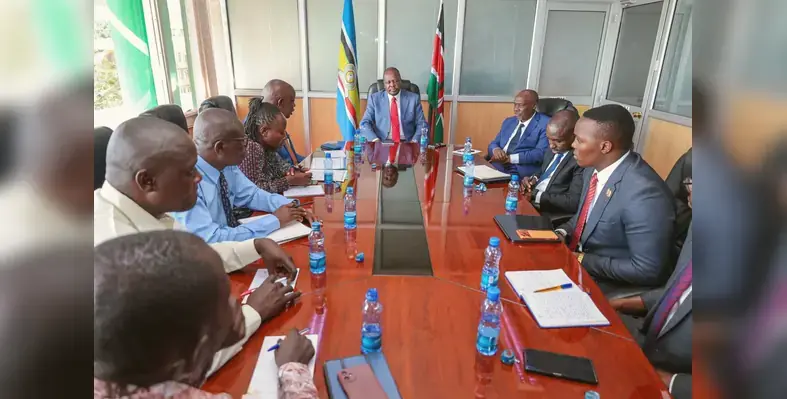

The meeting was chaired by the Cabinet Secretary for Agriculture and Livestock Development, Mutahi Kagwe, and brought together key players in the industry. Among those present were Agriculture Principal Secretary Kipronoh Ronoh, Kenya Sugar Board chief executive officer Jude Chesire, Chair of the Sugar Transition Committee Harun Khator, and KUSPAW leaders led by General Secretary Francis Wangara.

The industrial action had begun on January 29, 2026, affecting operations at Muhoroni, Nzoia, Sony and Chemelil sugar factories. Workers downed their tools over unpaid salary arrears and terminal benefits amounting to KSh10.8 billion, owed to both current and former employees. The prolonged dispute had disrupted production and deepened hardship for thousands of families in sugar growing regions.

After lengthy deliberations, the parties reached an agreement that will see workers return to duty as the Government moves to settle the outstanding arrears. Under the deal, the strike was suspended with immediate effect, while KSh1 billion is set to be released within the next two weeks to ease acute financial pressure on workers. The remaining balance will be addressed through the Supplementary Budget and future budget allocations, with Parliament expected to approve the funding. Payments will be made in phases covering salary arrears, redundancy dues, pensions and other terminal benefits.

CS Kagwe, said, “As Government, we accept responsibility for these debts. The arrears are owed by the Government, not private millers. We will push Parliament hard to resolve this matter conclusively through the Supplementary Budget so that the sugar sector is stabilized once and for all.”

He stressed that private millers leasing the factories are not responsible for the legacy debts and warned that targeting third parties only prolongs worker suffering and undermines sector recovery.

KUSPAW General Secretary Francis Wangara welcomed the renewed commitment, noting the dire conditions faced by exited workers. “We have agreed to suspend the strike in good faith as we monitor the release of funds and implementation of agreed milestones. Workers have suffered long enough, and this matter must now be resolved conclusively,” Wangara said.