The Government of Zimbabwe has commenced updating its antimicrobial resistance (AMR) National Action Plan (NAP) 2023-2027, to replace the previous NAP (2017-2021) which had lapsed

Poultry

Aviagen East Africa delivers first parent stock chick shipment to Uganda and Tanzania

In recent months, Aviagen East Africa delivered its first shipment of Ross Parent Stock (PS) to Biyinzika Poultry International in Uganda and Harsho Milling Company Limited in Tanzania

Power cuts prompt farmers to cull around 10 million chicks in South Africa

Consistent blackouts in South Africa have left poultry farmers struggling with low production, processing backlogs and hardly any room for chicks, resulting in the unfortunate need to cull more than 10 million chicks within a matter of weeks

CERSA and WPSA collaborate to organise second Pan-African Poultry Conference

The Regional Centre of Excellence for Poultry Science (CERSA), University of Lome, and World Poultry Science Association (WPSA-Togo branch) are co-organising the second edition of the Pan-African Poultry Conference (PPC) from 16-18 May 2023, with the theme: ‘Competitiveness and inclusiveness of the value chains of the poultry sector in Africa

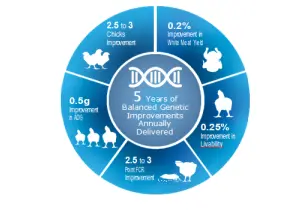

Ross 308: The Broiler of Choice in Sub-Saharan Africa

Bulent Tanyildizi, international commercial manager, MEA discussed why the Ross 308 is the broiler of choice in this continuously growing and dynamic region