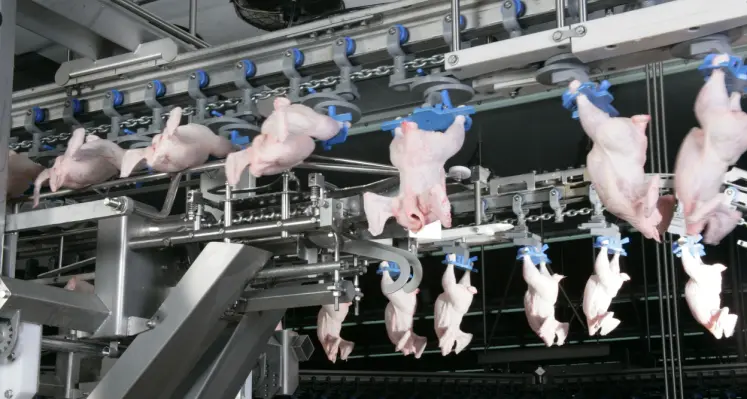

Mechanisation makes farming attractive to younger generations due to its reduced reliance on manual labour. (Image source: Adobe Stock))

Ahead of the 2024 planting season, ag-tech company Hello Tractor joins hands with the Ekiti Ministry of Agricultural Development and Food Security, to boost mechanisation and improve food security in the Nigerian state of Ekiti